Why Pick Expert Welding Inspection Madison for Your Tasks

Wiki Article

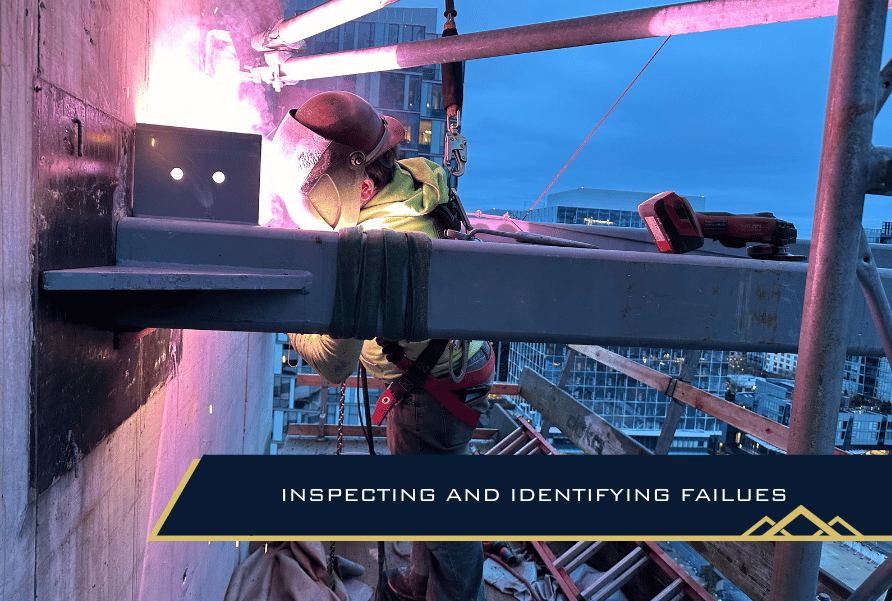

Just How Reliable Welding Evaluation Improves Structural Integrity and Longevity

In the world of building and construction and engineering, the relevance of welding assessment can not be overemphasized, as it plays a pivotal duty in making certain structural integrity and expanding the lifespan of jobs. Sign up with the expedition of how effective welding evaluations can transform potential vulnerabilities into toughness, contributing to the enduring success of buildings.Importance of Welding Evaluation

Guaranteeing the architectural honesty and security of welded buildings mandates strenuous welding assessment processes. Welding assessment serves as a vital guard in the building and construction and manufacturing industries, where the stamina and durability of joints dramatically influence the general performance of structures.In addition to safety and security, welding assessment plays a vital function in top quality guarantee. Industry criteria and codes, such as those from the American Welding Culture (AWS) or the International Company for Standardization (ISO), necessitate adherence to stringent standards, highlighting the importance of inspections in fulfilling these lawful and expert obligations.

Key Inspection Techniques

Ultrasonic Testing (UT) utilizes high-frequency acoustic waves to identify subsurface imperfections, offering exact details about weld integrity without causing any damages. Radiographic Evaluating (RT), including X-rays or gamma rays, gives a detailed photo of the weld's interior structure, revealing concealed flaws. Magnetic Fragment Examining (MPT) is one more non-destructive approach, particularly reliable for spotting surface area and near-surface stoppages in ferromagnetic products.

Penetrant Testing (PT) includes the application of a liquid color to disclose surface-breaking flaws, providing a simple and cost-efficient option for non-porous materials. Each method has its particular applications, strengths, and constraints, and commonly a combination of approaches is used to attain extensive evaluation results. Mastery of these techniques improves the integrity and sturdiness of bonded structures, straightening with security and performance assumptions.

Identifying Common Defects

Porosity, defined by gas pockets within the weld, minimizes the weld's strength and toughness. It usually results from impurities or incorrect securing gas. Fractures, which can occur throughout or after welding, posture significant dangers due to their possible to circulate under stress. They usually occur from extreme anxiety, fast air conditioning, or incorrect weld design.

Insufficient fusion, where the weld steel fails to bond totally with the base material, weakens the architectural integrity, leading to weak joints. Slag inclusions occur when non-metallic products are entraped in the weld, endangering its stamina and quality.

Identifying these defects through thorough examination methods, such as visual assessment, ultrasonic testing, or radiography, is vital. Attending to these issues makes certain weld click reference high quality, eventually sustaining the structural integrity and safety and security of the built atmosphere.

Enhancing Architectural Performance

Comprehending the value of recognizing usual weld problems normally results in exploring techniques for boosting architectural performance. The fundamental approach for boosting performance requires using sophisticated welding strategies and materials that mitigate flaw incident. Utilizing top quality filler products and ensuring correct warmth control can substantially decrease problems such as porosity and cracking, consequently enhancing the weld's stability.Incorporating advanced welding innovations, such as laser welding and rubbing mix welding, more magnifies architectural durability. These strategies offer exceptional precision and lowered thermal distortion, directly affecting the durability and stamina of the welded frameworks. In addition, adopting automated welding systems can make certain repeatable and consistent weld quality, reducing human mistake.

In addition, executing extensive pre-weld and post-weld treatments is vital. Correct joint design, surface preparation, and stress-relieving procedures contribute to read here optimum weld performance. Carrying out extensive pre-weld evaluations permits early detection of prospective concerns, assisting in prompt improvements before they compromise the structure.

Long-term Advantages of Evaluation

With alert inspection techniques, the long-term advantages to structural honesty become progressively noticeable. Consistent and thorough welding inspections play a vital role in preventing architectural failures by recognizing disparities and issues early in the building and construction process.

Additionally, regular assessments add to maintaining conformity with sector requirements and guidelines, consequently staying clear of economic and legal repercussions. This adherence to quality control not just improves the reliability of the structure yet also cultivates depend on amongst stakeholders, including customers, engineers, and governing bodies. The thorough documents of evaluation outcomes functions as a beneficial resource for future repair and maintenance initiatives, facilitating educated decision-making.

On top of that, reliable inspection practices sustain technology by integrating advanced technologies such as non-destructive screening and digital imaging, which can boost precision and efficiency. This technical Recommended Reading assimilation further emphasizes the dedication to excellence in structural stability. Eventually, purchasing careful welding examinations is a prudent strategy that produces substantial long-term benefits, securing both the physical and economic financial investment in facilities jobs.

Verdict

Reliable welding assessment plays an essential role in improving architectural stability and longevity by identifying defects early in the building and construction process. Utilizing methods such as aesthetic inspection, ultrasonic screening, and radiographic screening guarantees the detection of problems like fractures and porosity that jeopardize weld stamina. Rigorous inspections ensure compliance with industry criteria, thereby lengthening the lifespan of frameworks, reducing costly repair services, and cultivating stakeholder depend on in the reliability and safety of welded constructions.

In the world of construction and engineering, the significance of welding inspection can not be overemphasized, as it plays a critical role in guaranteeing structural stability and extending the life expectancy of tasks.Guaranteeing the architectural honesty and security of welded buildings mandates extensive welding evaluation processes.Structure upon the value of welding examination in securing structural stability, recognizing the vital evaluation methods becomes crucial for reliable execution. Efficient welding assessment incorporates an array of methods designed to assess weld quality, making certain conformity with rigid engineering requirements - Welding Inspection Madison.Effective welding evaluation plays a critical duty in boosting architectural stability and longevity by recognizing issues early in the building and construction process

Report this wiki page